Microsoft Dynamics 365 Asset Management

Better ways to manage assets

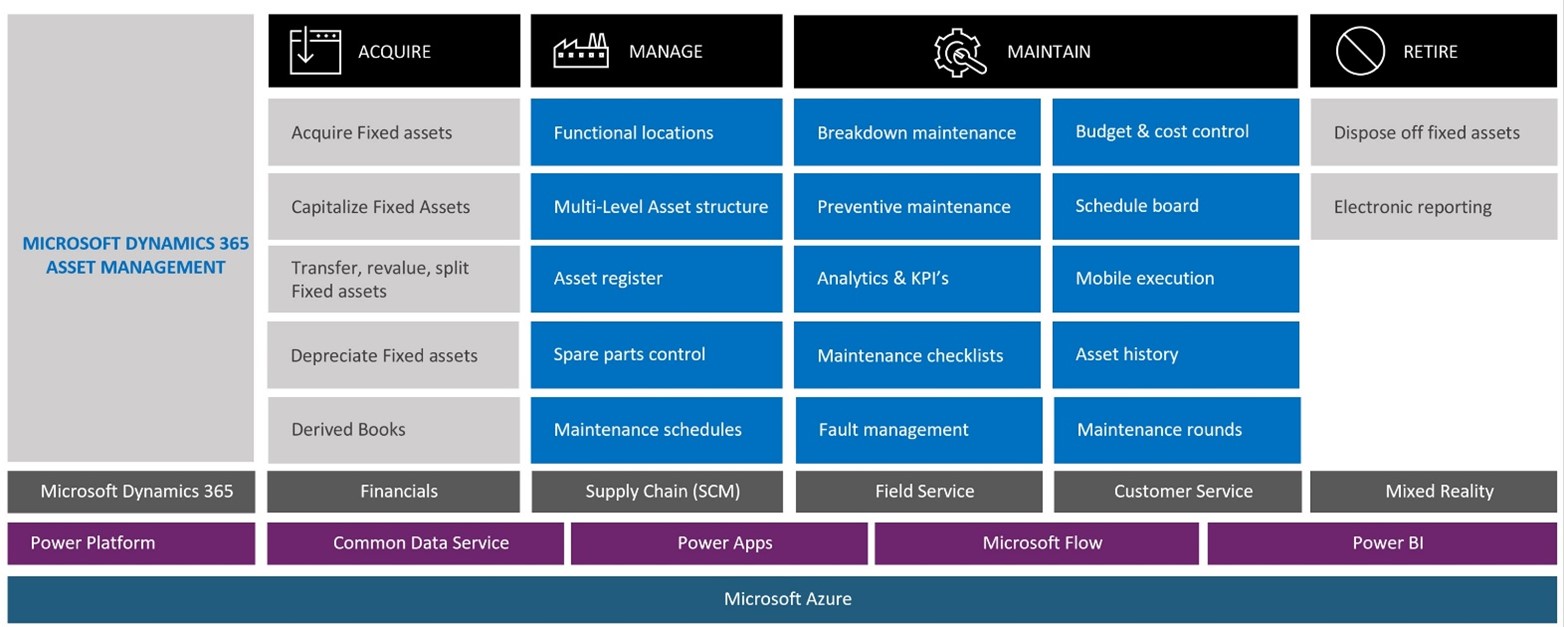

Microsoft Dynamics 365 Asset Management – is an advanced module designed to manage fixed assets (assets) of the enterprise, focused on reducing the cost of maintenance, repairs and logistics without compromising the level of reliability. The module helps to achieve the maximum possible uptime of an asset, its efficient operation, and predictability in use. Includes the management and maintenance of the organization physical assets throughout the life cycle of each.

The functionality of Microsoft Dynamics 365 Asset Management, allows you to build an effective process for managing various types of assets, considering their location, design, operating mode, the manufacturer’s recommended scheduled maintenance policy, warranty conditions, emergency repair statistics, and other costs throughout the entire life cycle. It provides the ability to maximize asset life, reduce maintenance costs and downtime, and improve planning efficiency.

Microsoft Dynamics 365 Asset Management is a part of Microsoft Dynamics 365 Supply Chain Management solution, and is easily integrated with other modules, in particular with Finance and others.

The assets can be your own:

- Buildings and structures;

- Vehicles and any other mobile equipment;

- Production equipment;

- Expensive, long term equipment, inventory

The system also allows you to manage leased assets or customer equipment if the company is engaged in its maintenance.

Key features of Microsoft Dynamics 365 Asset Management include:

- Tracking. Assumes maintaining a complex classification of assets based on a hierarchy of values

- Preventive maintenance. Allows you to manage the needs for planned maintenance of assets, based on manufacturer’s recommendations, thereby making it possible to prevent unexpected equipment failures.

- The scheduled maintenance date is calculated based on the parameters from the manufacturer’s technical documentation entered the system. This allows maintenance work to be planned. The data is collected in a calendar, which serves as the basis for a timetable-driven work order. When equipment, or any other type of asset, needs urgent emergency repairs, it is possible to create special work orders and build them into the existing planned schedule.

- Managing a team of specialists who can perform certain types of work related to the assets repair or maintenance.

- Maintaining maintenance checklists, which contain a list of actions to be performed by an employee when performing asset repairs or maintenance.

- Forecast of materials and spare parts consumption that are required to carry out assets repairs or maintenance. Based on such a forecast, a procurement plan for the necessary items can be formed.

- Ability to work with the module on different devices, including smartphones.

- Graphical representation of the plan for the execution of repairs and maintenance of assets (Gantt chart).

- Work order management and equipment operation planning. Based on a few parameters, for example, such as working capacity, criticality of the work order, etc.

- Planning, control and analysis of asset maintenance costs.

- Key Performance Indicators (KPIs) provide a set of analytical data to measure the asset performance, allowing you to monitor and evaluate its effective usage.

Want to reduce equipment downtime, easily manage geographically dispersed assets, improve equipment performance?

Select processes which system should cover

Join the success stories!

Our Mission Is to Empower

0+

Projects

0+

Years of expertise

0+

Years Microsoft Solutions Partner

For over 20 years, Innoware has been transforming enterprises around the globe, optimizing business processes, implementing and supporting ERP and CRM systems for business process management, AZURE cloud solutions, Microsoft 365 for business, and Microsoft Dynamics 365.

Thanks to our unique project methodology we know exactly how to manage complex projects while ensuring high-quality implementation services are delivered to all clients.

Innoware has fulfilled more than 500 ERP projects in the manufacturing, distribution, and retail business. Our implementation management methodology is a key to achieving defined business value depending on business size, operational processes, and business niche.

INNOWARE USA

501 Silverside Rd, Ste 105, # 4995,

Wilmington, Delaware, 19809-1376,

United States

Tel.: +1(302)4672024

E-mail: info@innoware.com

Local Contact – United Arab Emirates

Dubai

Tel.: +971588894591

E-mail: info@innoware.com

INNOWARE UKRAINE

3, Sholudenka Str., office 204 (Cubic BC)

Kyiv, Ukraine, 04116

Tel.: +380(44)4902220

E-mail: info@innoware.com