Implementation of Microsoft Dynamics NAV in PJSC «Zhytomyr butter plant» – «RUD»

Transparence in commodity transportation organization

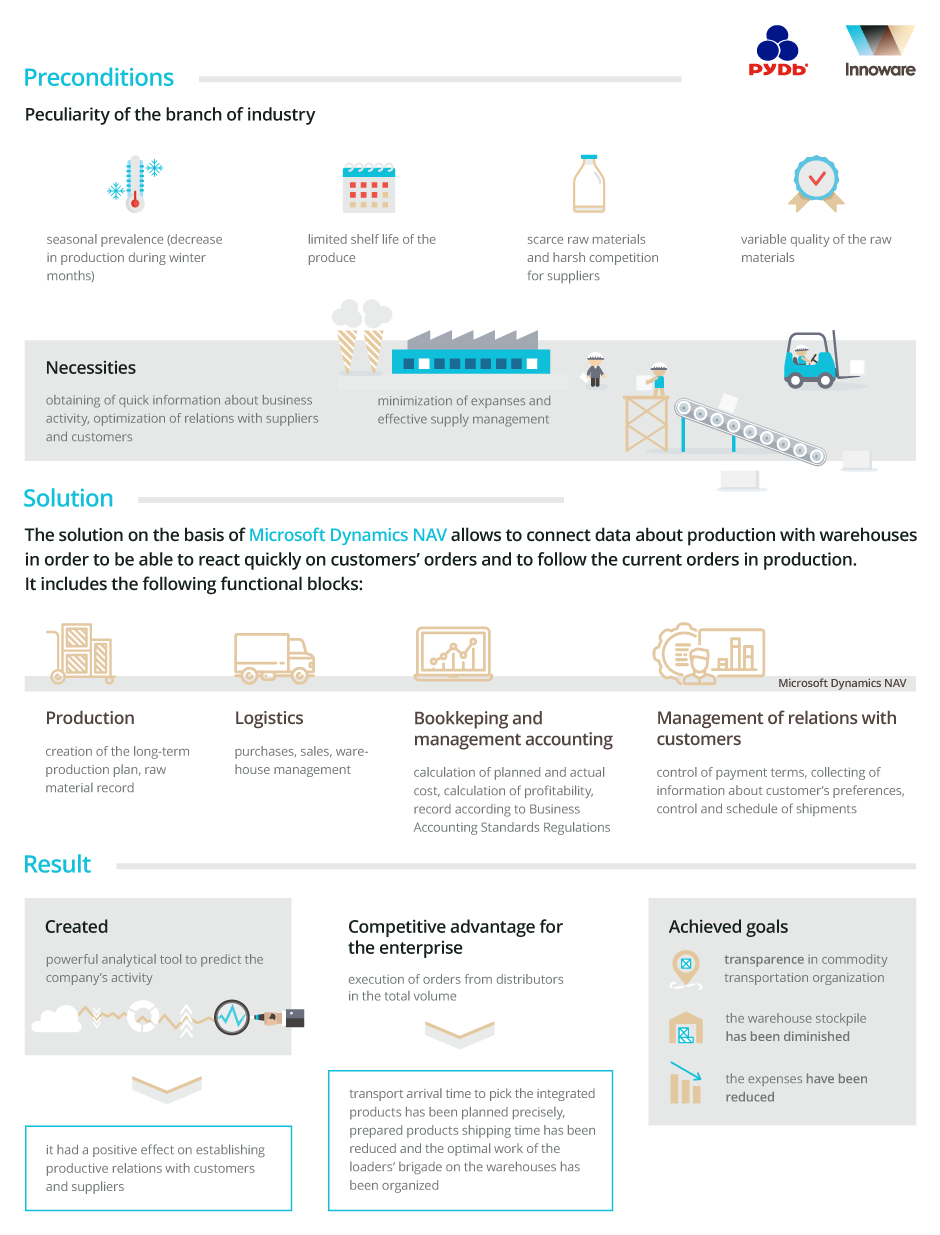

Peculiarity of the branch of industry:

- Seasonal prevalence (decrease in production during winter months reaches 10% of the total plant capacity);

- Limited shelf life of the produce;

- Scarce raw materials and harsh competition for suppliers;

- Variable quality of the raw materials (milk) and, as a result, instability of composition.

Organizational and commercial preconditions:

- Lack of quick access to the information about product supply and consumption has complicated planning of purchases and production.

- Lack of interaction system with suppliers has resulted into unprofitable contracts for the enterprise.

- Increasing competition with popular foreign brands has caused danger of the market leading position preservation.

It was crucial to ensure production and selling of the maximum quantity of the produce during short season, since the penetration threshold of new players to the Ukrainian market is pretty low.

Critically increased necessity to receive quick information about business activity, optimization of relations with suppliers and customers, minimization of expenses and optimization of production planning, and as a result, it has shown the necessity to implement ERP system. To solve these tasks, company management has chosen the enterprise resources management system Mіcrosoft Dynamіcs NAV to change the local accounting system and to ensure proper functionality according to increased demands.

The choice of the Mіcrosoft Dynamіcs NAV system by the management of PJSC “Zhytomyr Butter Plant” was dictated both by the vast basic functionality of the product and by the possibility to satisfy specific demands connected with branch peculiarity.

Solution

Innoware consultants offered solution on the basis of Mіcrosoft Dynamіcs NAV, which includes the following functional blocks:

- Production (raw materials record);

- Logistics (purchase, sales, warehouse management);

- Bookkeeping and financial accounting;

- Customer relationship management (control of payment terms, collecting of statistic information about customer’s preferences, control and schedule of shipments).

The solution allows to connect data about production with warehouses in order to be able to react quickly on customers’ orders and to follow the current orders in production.

Also, unified standards on the basis of production business processes were offered to be implemented:

- Data management about integrated products, including information management on production sectors – workshops and technological routes;

- Acceptance of orders;

- Management of workshop production and workshop control (including taking into account such indexes as discards’ record, variants’ record);

- Distribution of transport expenses according to types of raw materials.

Creation of the long-term production plan of the line of integrated products before the implementation of Mіcrosoft Dynamіcs NAV was practically impossible due to the peculiarity of demand from main customers of PJSC “Zhytomyr Butter Plant” produce. To solve this issue effectively, Innoware consultants have offered implementation of the production module. It allows to make specified quick production plan, to calculate needs in raw-stuff, materials and prepared raw materials on the basis of the accepted orders taking into account already formed production plan-schedule and existing supply of the raw materials.

It creates additional competitive advantage for the butter plant – execution of orders from distributors in the total volume. It allows to plan precisely transport arrival time to pick the prepared products, to reduce their shipping time and to organize the optimal work of the loaders’ brigade on the warehouses.

To solve the branch peculiarity of the enterprise in the field of purchases, the counteragent reference book was elaborated taking into account such sections: contact information, division on districts and villages, shipping and purchase conditions, binding of cost to counteragent.

When purchasing milk, the record of milk in basic and natural representation is kept. In addition to that, for the needs of the highly technological production of ice-cream, the record of the qualitative characteristics of milk was implemented: fat content, density / protein, grade of quality, cooling, impurity.

The result

As a result of implementation of the solution, the enterprise has received transparence in commodity transportation organization, the warehouse stockpile has been diminished and the expanses have been reduced. The butter plant management has received a powerful analytical tool to predict the company’s activity, and as a consequence it had a positive effect on establishing productive relations with customers and suppliers.

Within the framework of the project, the following tasks were accomplished:

- Regulation of management accounting, which contains description and forms of elaborated primary documents and reports, documents filling in and processing sequence, lists of the responsible executors, documents’ filling in terms, etc.

- Calculation of the planned cost.

- Planning taking into account qualitative characteristics of raw materials and integrated products, existing standards and budgets.

- Approaches to the optimization of the commodity production portfolio.

- Planning and forming of the produce portfolio depending on the expected volumes of milk processing.

- Elaboration of the raw materials transportation procedures.

- Control and record of the raw materials’ consumption, calculation of the raw materials cost in each consignment of the produce taking into account qualitative characteristics of the raw material and current milk payment system.

- Raw materials write-off according to the method “from raw materials” without application of the aggressive standards per ton of the produce.

- Electronic models of the production reports.

- Elaboration of the approaches for the calculation of the protein value, fat content and raw material in general depending on the produce being manufactured, the raw materials’ characteristics being used and current milk payment system of the enterprise.

- Calculation of the produce profitability per ton of the raw materials being used according to the DSTU (State Standards of Ukraine).

- Elaboration of the transport expenses planning, optimization and control model.

Select business processes which system should cover

Join the success stories!

Our Mission Is to Empower

0+

Projects

0+

Years of expertise

0+

Years Microsoft Solutions Partner

For over 20 years, Innoware has been transforming enterprises around the globe, optimizing business processes, implementing and supporting ERP and CRM systems for business process management, AZURE cloud solutions, Microsoft 365 for business, and Microsoft Dynamics 365.

Thanks to our unique project methodology we know exactly how to manage complex projects while ensuring high-quality implementation services are delivered to all clients.

Innoware has fulfilled more than 500 ERP projects in the manufacturing, distribution, and retail business. Our implementation management methodology is a key to achieving defined business value depending on business size, operational processes, and business niche.

INNOWARE USA

501 Silverside Rd, Ste 105, # 4995,

Wilmington, Delaware, 19809-1376,

United States

Tel.: +1(302)4672024

E-mail: info@innoware.com

Local Contact – United Arab Emirates

Dubai

Tel.: +971588894591

E-mail: info@innoware.com

INNOWARE UKRAINE

3, Sholudenka Str., office 204 (Cubic BC)

Kyiv, Ukraine, 04116

Tel.: +380(44)4902220

E-mail: info@innoware.com